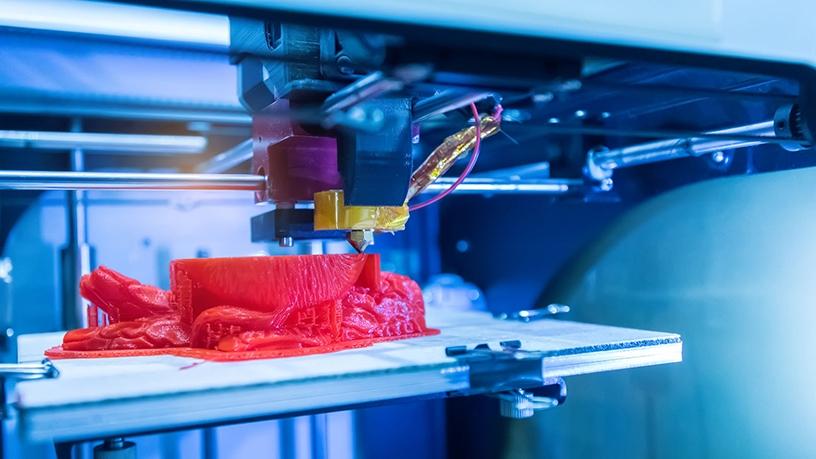

When it comes to manufacturing prototypes, nylon 3d printing is the wave of the future. The use of lasers has proven to be helpful in many different applications, from laser eye surgery to laser fingerprint scans. Polyamide proves their effectiveness they can be used to improve production technology. Through the process of nylon 3D printing, it is possible to make prototypes of metal components. This technology can create made of many different kinds of metals and is very simple to use. Whatever the part you require, you can make it. Nylon 3D printing is a process by which metal powder sintered into layers. These layers are sintered together till the desired thickness is reached by them. They need support structures, which are made from metal’s incorporation. After sintering is complete these support structures could be eliminated. The prototype may require some extra work in order such as heat treatment, shot peening, and processes. The end result is a durable prototype which can enable you to work out whether your new layout will work.

You can use nylon 3D printing to make prototypes from an assortment of metals. You can make parts from ceramic, stainless steel, Inconel, Hastalloy, and chrome. Nylon 3d printing applies powdered metal in layers, and technology is continuing to proceed on those innovations. You will have the ability to use this technology on the kinds of alloys and metals you can get your prototypes made in the metals that you need for efficiency and maximum durability. Your prototypes will be so great that you may have the ability to use them in production. Nylon 3d printing singapore took there is to be developed, some time moving with Metals and innovations in the area. There are sure to be more improvements to the technology of nylon 3d printing, and when this process is the production world can look forward to more, any indication Efficient and cost-effective prototyping technologies.

Leave a Reply